Origin: Open Additive Manufacturing

At Origin, I gained experience in design and quality engineering in the early release stage of the Origin One DLP printer. Origin’s open materials network expands the range and availability of materials in additive manufacturing.

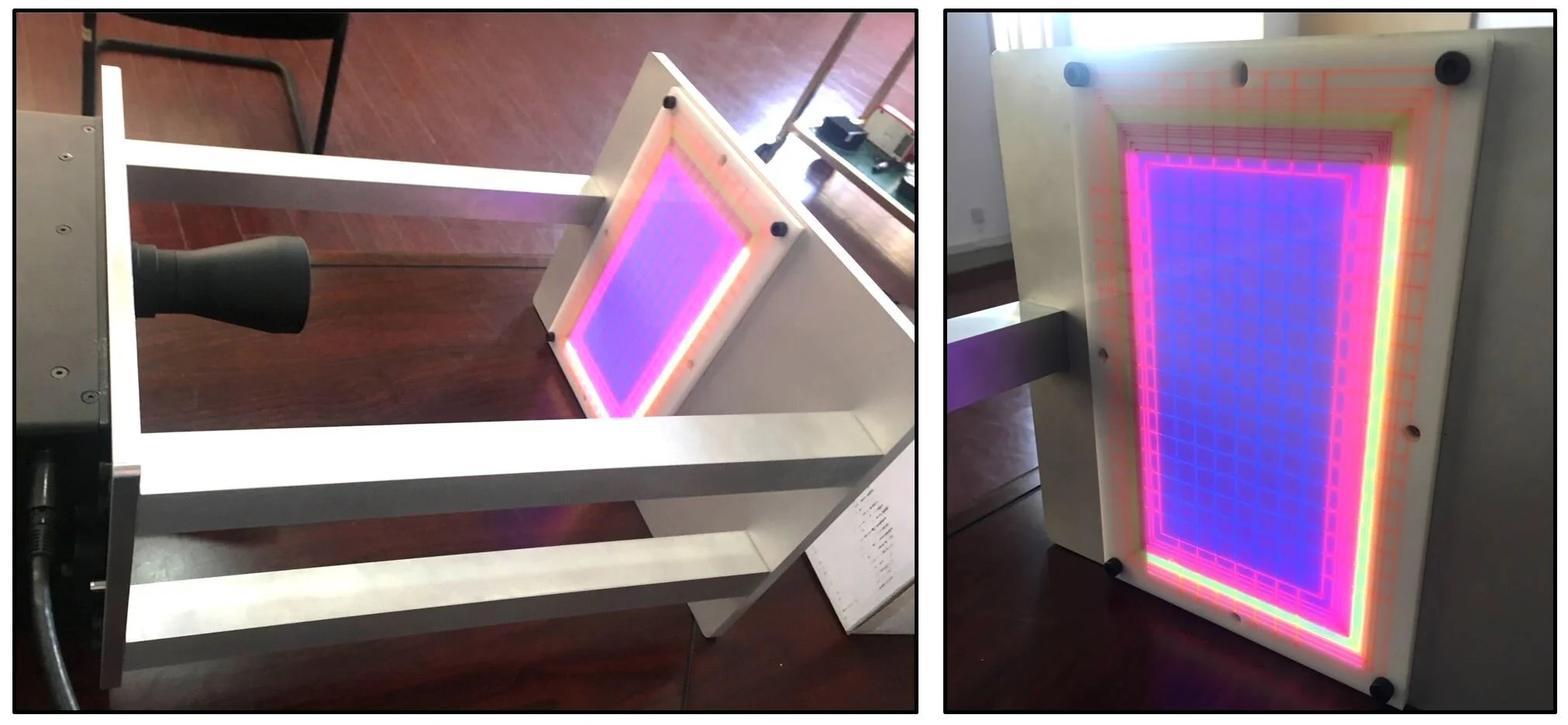

Projector Image Quality Test Rig

Designed a test rig to detect keystoning and image translation during on-site quality testing with the contract manufacturer. A mounting plate connected to a projection plate provides a surface on which to test the accuracy of the image projection. An acrylic plate enscribed with error bounds allows image translation and keystoning to be quickly and easily visualized.

Design Overview

The rig can be quickly assembled and dissembled, allowing for quick error analysis on-site at the contract manufacturer.

Precision locating features connect the mounting plate to the projector, centering a projection surface over the lens.

Using tolerance stacks, rods maintain an accurate throw between the lens and projection area.

Error bounds were calculated and laser etched into an acrylic projection plate. The lines were coated in UV reactive paint, color coded to various error boundaries.

When light is projected onto the plate, a quick visualization of error can be made (see bottom images)

Results

Error visualization is depicted below, with the yellow light corresponding to image translation.

Using this rig, an image translation of 10mm from nominal was found at the manufacturing site, enabling critical improvements in quality control.