Additive Manufacturing Graduate Projects (ME 557)

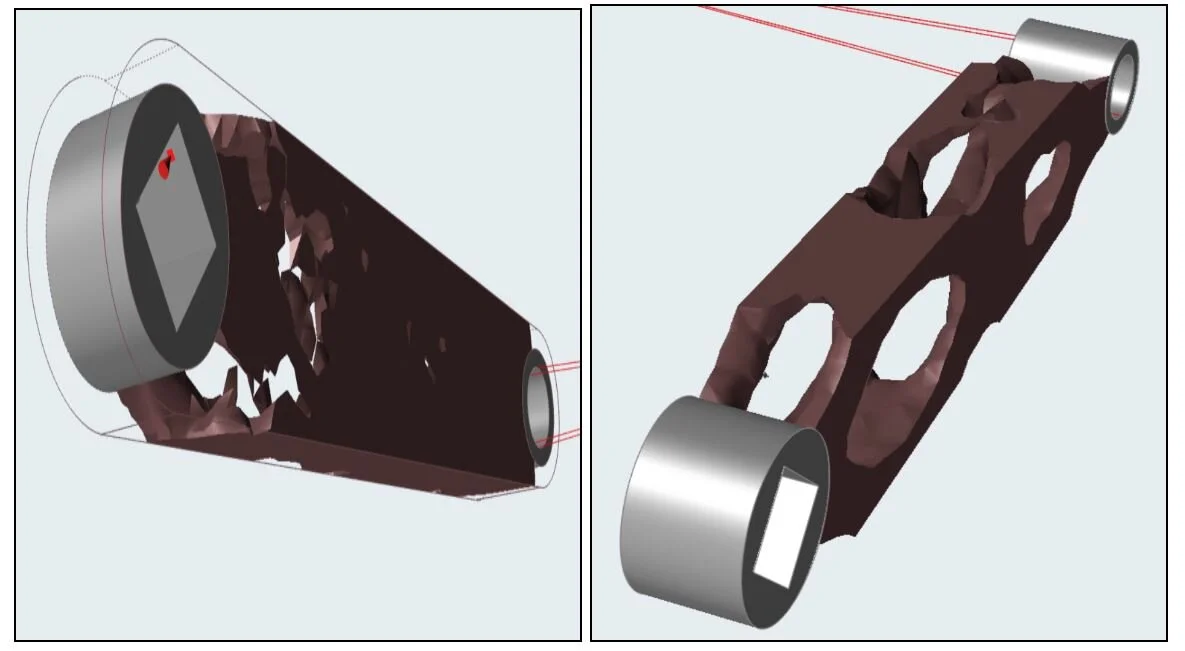

Topological Optimization - Bike Crank

Topological optimization allows the structural design of a component to be optimized while reducing material and weight.

We chose a simple bike crank arm with a diamond hole feature that attaches to a spindle and a circular hole that attaches to the bike pedal. In the real world, a bike crank is subjected to various dynamic loads that could translate to structural improvements using topological optimization.

1st Iteration, Inspire setup:

Fixed the bike crank arm and applied the force of the biker on the pedal in one direction.

A point load was applied where the crank attaches to the spindle and moved to the pedal location.

Symmetry was applied along all 3 axes using shape controls .

Result:

An optimization was generated with 1000N force exerted on a bike pedal.

The increased load can be considered a safety factor from the normal load applied on a bike crank.

In this iteration, the optimization removed critical supporting material around the joints.

Second iteration, Inspire setup:

Compressive loads were added in positive and negative vertical directions, an additional load to simulate the other pedal, and a moment to simulate a biker shifting weight.

After the optimization, material towards the center of the bike crank was removed. This made sense from a mechanical perspective as the remaining material was necessary for load support.

Result:

The part was re-modeled in SolidWorks from Insire parameters and printed on the Form 2 SLA printer.

Through part orientation, we avoided using supports on the holes, maintaining hole tolerances.

The minimal support usage on the flat side guaranteed a nice print with smooth surface finish.