Modular Desktop Organizer (ME 537 - Product Realization)

This course focused on bringing a design from prototype to large scale manufacturing, culminating in a production line of 10 units. Topics included design for manufacturing, EVT through PVT, specifications documents, Gantt charts, validation testing, cash flow modeling, distribution, and product support.

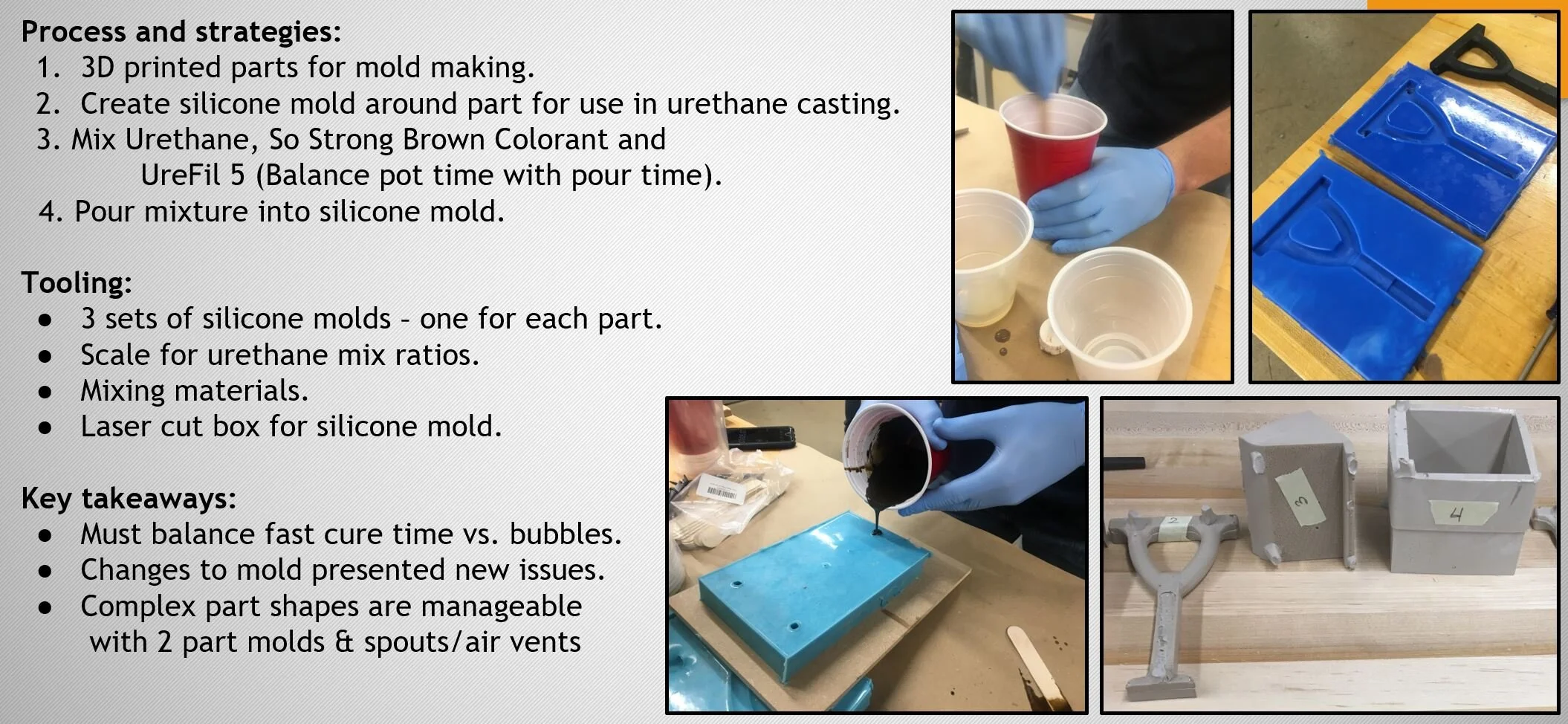

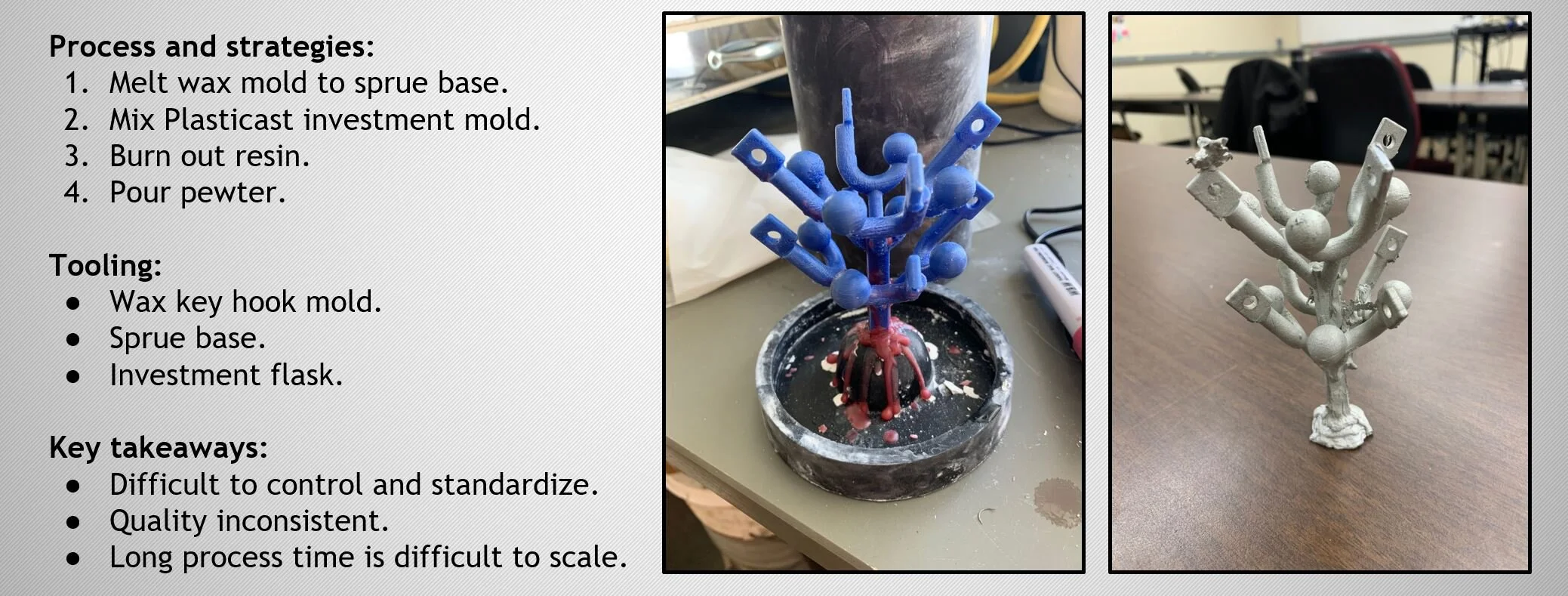

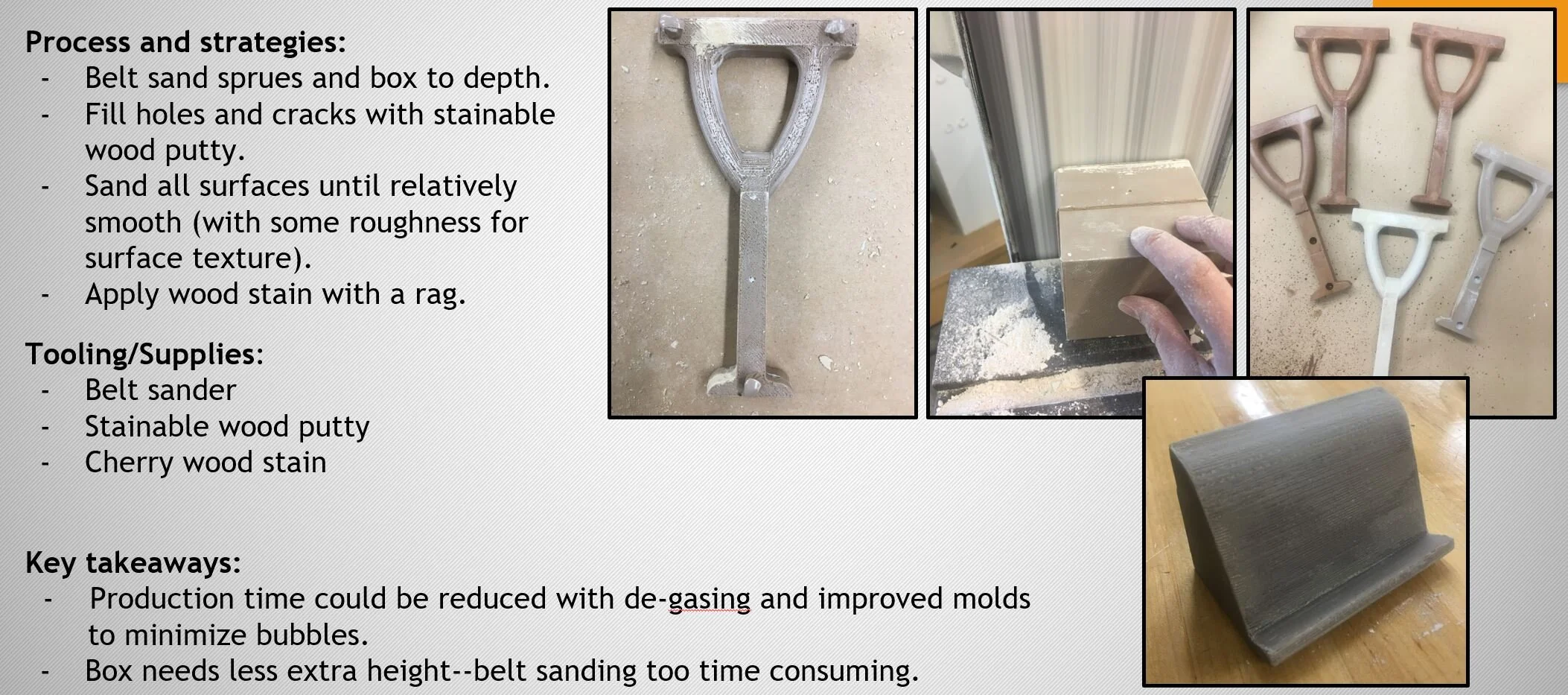

Manufacturing techniques involved prototype and mold making via additive models, urethane casting, investment casting, and machining. After the prior caliper box project, this course advanced my understanding of managing a scaled production line.

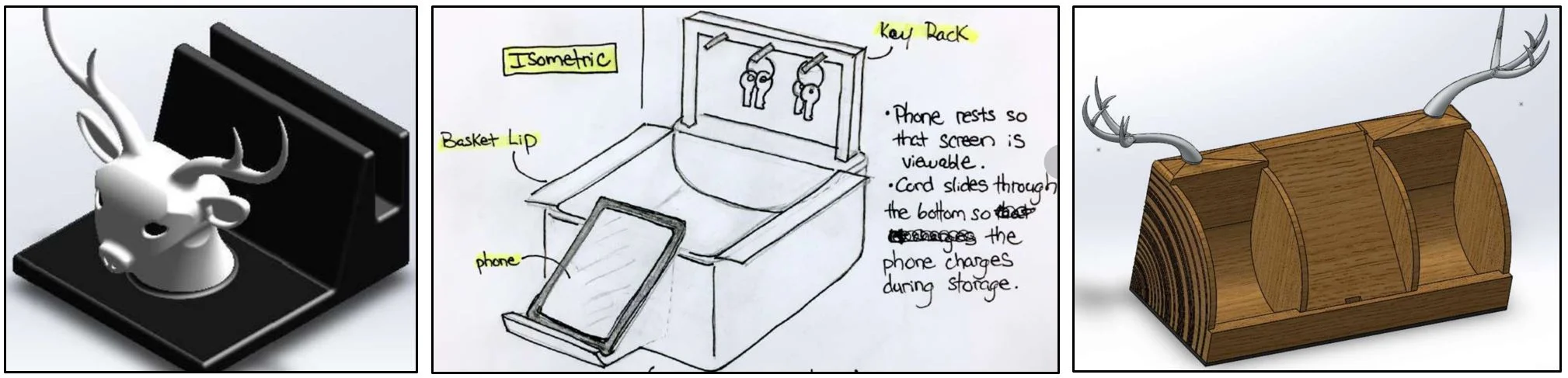

Initial concept and brainstorming

The initial concept was to design a multi-function desktop organizer.

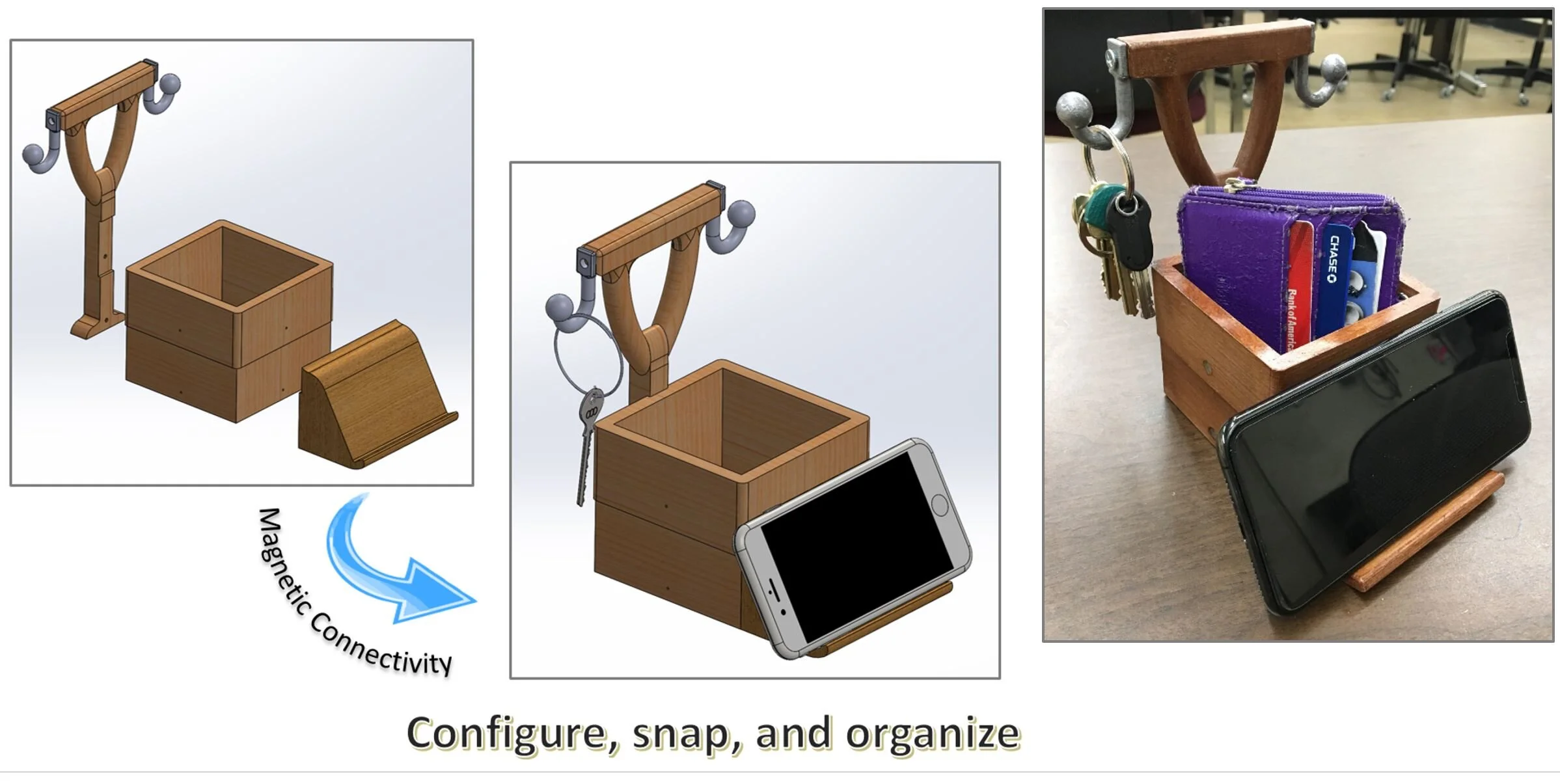

Brainstorming resulted in two main concepts: a letter holder with a “deer head” key rack and a rectangular box with storage compartment, phone holder, and key rack.

In the first prototype, concepts were combined by including the antler hooks and a natural wood aesthetic with phone and storage compartments.

Due to complexity, design simplification was needed for successful urethane casting.

Final Design

Modularity: Three main pieces: container, phone holder, and pewter key hook tree. Additional components purchased separately allow unlimited customization.

Magnets: Each of the pieces contains magnets embedded in the walls, allowing components to attach additional components.

Aesthetic: Rough surface finish painted with wood stain creates a “rustic” aesthetic.