Origin: Open Additive Manufacturing

At Origin, I gained experience in design and quality engineering in the early release stage of the Origin One DLP printer. Origin’s open materials network expands the range and availability of materials in additive manufacturing.

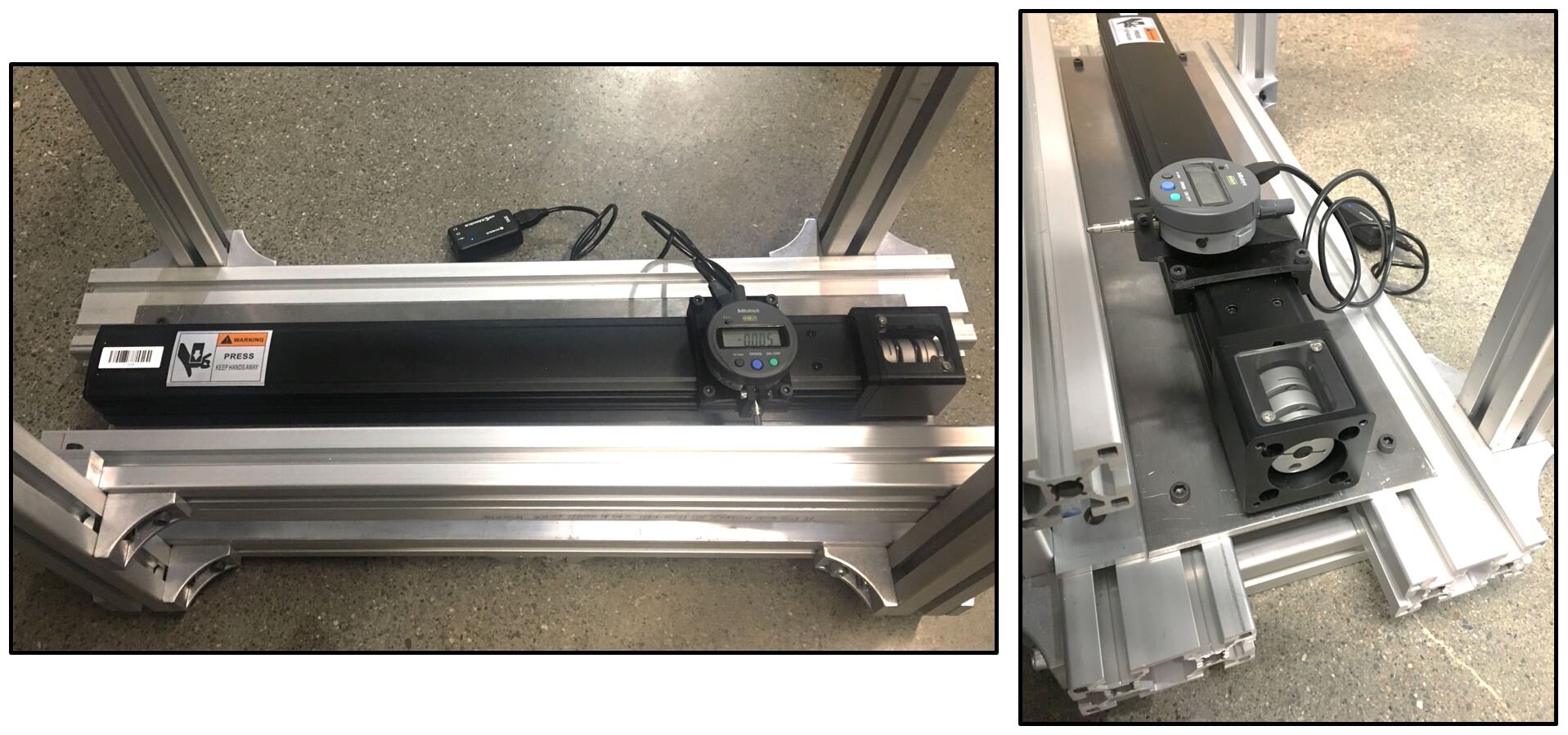

Linear Stage “Wobble” Test Rig

Design Overview

Developed a test rig to measure “wobble” along length of the linear drive, establishing a quality control system for new drives.

A dial indicator was used to assess variation in motion on the z-stage actuators.

The z-movement standard deviation was derived from the standard print setting layer height.

Designed a parallelism adjustment to normalize the slope for accurate “wobble” analysis.

Testing Process

Each linear drive was mounted and installed into the test rig.

A 3D printed dial indicator fixture was mounted to the linear stage and the indicator installed.

During testing, the dial indicator touches off along a bar parallel to the linear drive.

The parallel bar is spring loaded and can be manually adjusted with a hex wrench to lie parallel with the linear drive, normalizing the slope.

Data was collected in excel and analyzed in MATLAB, allowing drives to be sorted for manufacturing priority and traceability.