Investment Casting - Jewelry Making from 3D-printed Molds

Investment Casting is a manufacturing process in which metal parts are created through a complex process of mold making and metal pouring. Additive manufacturing allows greater flexibility in design and repeatability than traditional casting.

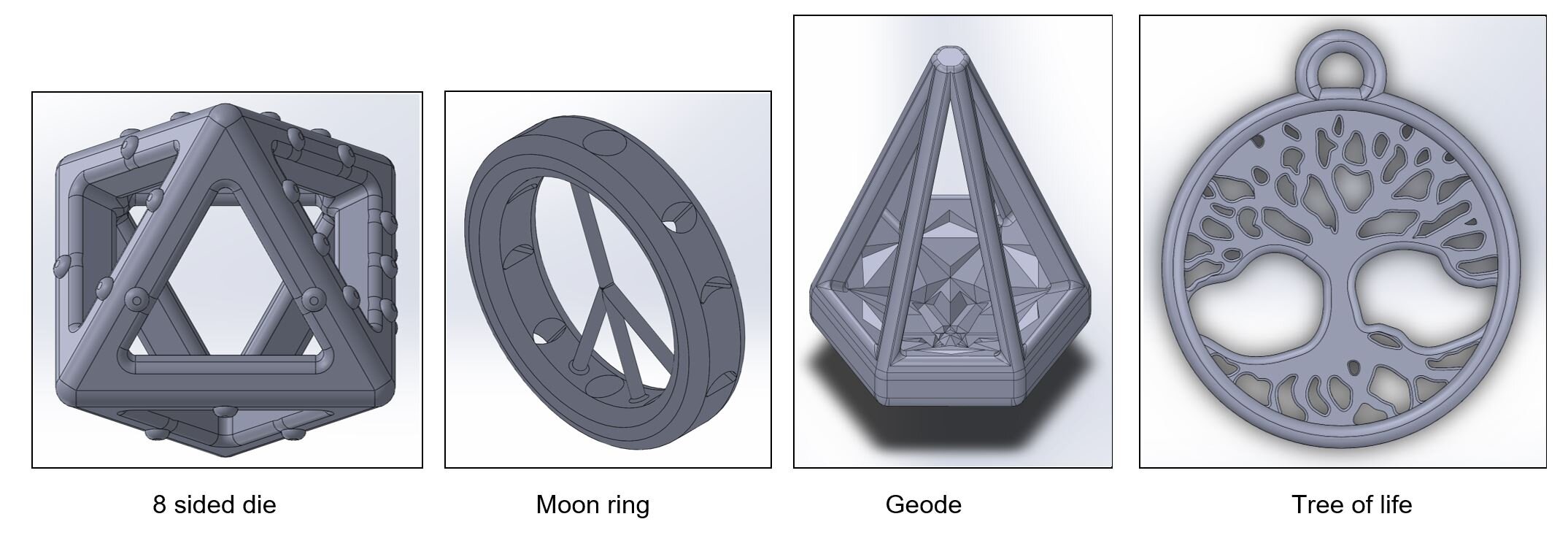

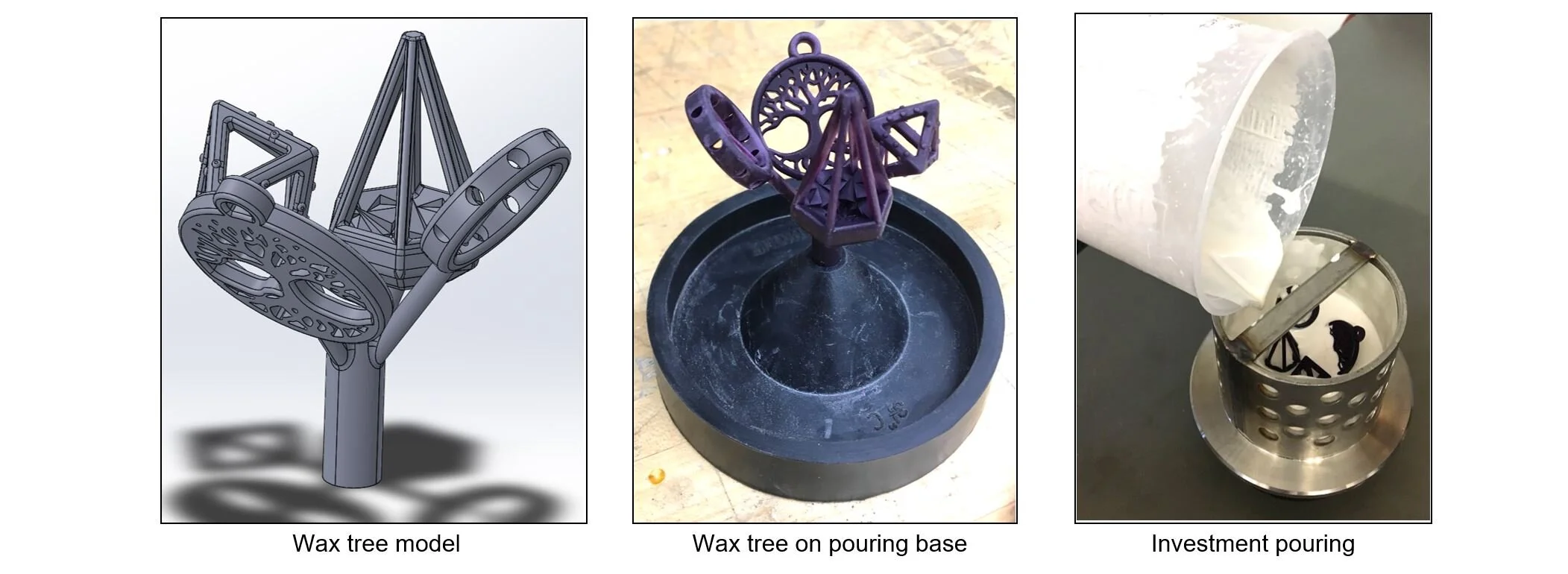

Four jewelry pieces were designed in SolidWorks and installed on a wax tree and printed in Formlabs castable wax resin. The tree contains a central sprue that provides a pathway for molten metal to follow as it is poured. The tree is covered in a plaster-like material (“investment”) and heated in a kiln to burn out the wax, leaving behind a cavity. Molten metal is poured into the cavity. After the metal solidifies, the investment cast is broken, revealing the completed parts.